Description

Fixed Doppler Flow Switch with Non-Contacting Sensor

- Installs in Minutes

- No moving parts

- Ideal for “difficult” liquids

- No contact, No maintenance

- Easy Calibration

Mounting

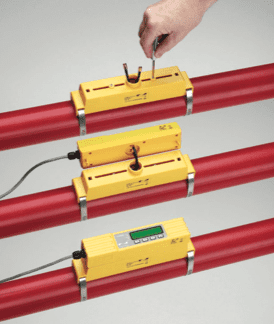

To begin with, to mount the fixed doppler flow switch on the outside of metal or plastic pipes, the sensor continuously injects high frequency sound through the pipe wall and into the moving fluid where it reflects back to the sensor from particles or bubbles in the fluid. As a result, this process accurately controls flow rates of most liquids, including acids, caustics, lubrication fluids, chemicals, abrasives, waste water, and sludge. Furthermore, it also eliminates the need for sensor maintenance since there are no moving parts.

In addition, the compact, water-tight electronics enclosure includes adjustable controls with separate ON and OFF relay set-points and time delay, plus a LED bar graph for flow rate and set points and relay status. Notably, you can install it while the flow system is in full operation, and it does not require contact with the moving fluid or drilling of holes in the pipe. As a result, this eliminates fouling or scale build-up on the sensor.

Applications

- Sewage

- Viscous liquids

- Acids

- Slurries

- Solvents

- Treated wastewater

- Sludge

- Pulp stock

- Food products

- Oils

- Paint

- Chemicals

- Aerated Water

- Cooling Water

STANDARD FEATURES

- SE4 sensor – clamp-on ultrasonic for 0.5-180” ID pipes

- Sensor cable – 20 ft shielded coaxial pair

- Installation – Silicone coupling compound

- Stainless steel Pipe Clamp Kit for 0.5-16” OD pipes

- Enclosure – water/dust-tight NEMA4X polycarbonate

- 1 Relay – 5 ampere DPDT

- Set point – On/Off adjustment 0.25 – 10 ft/sec

- Relay time delay – adjustable, 0-80 seconds

- Indication – Relay LED, Flow rate LED Bar Graph

- Power input – 100-240VAC 50-60Hz

- 1 Manual – Installation and Operation

Function

The Fixed Doppler Flow Switch, which utilizes the Doppler effect to detect fluid or gas movement within a pipeline or enclosed system, triggers an alarm or control mechanism once the flow exceeds a predetermined threshold. Furthermore, this device has a myriad of applications, such as:

- In a pumping system, using a Fixed Doppler Flow Switch can detect when the liquid flow falls below a specific level to prevent damage to the pump or other equipment.

- If a pipeline has a leak, it will reduce the flow of fluid. To detect this reduction in flow, one can use a Fixed Doppler Flow Switch, which triggers an alarm or shuts off the flow to prevent further damage.

- Fluid monitoring is a critical aspect of many applications. For instance, it is important to monitor the flow of fluid to ensure that it is within certain limits. To achieve this, a Fixed Doppler Flow Switch can be utilized. This device provides continuous monitoring of the flow rate, and triggers an alarm or control system if the flow falls outside of the desired range. Consequently, it enables prompt corrective action to be taken to prevent system failure or damage.

Process Control

- Process control is a critical aspect of industrial processes. Additionally, it is often necessary to monitor the flow of fluid to ensure that the process is running correctly. In order to achieve this, a Fixed Doppler Flow Switch can be utilized to provide feedback to the control system. With this feedback, the system can make adjustments as necessary, thereby optimizing the overall process performance. As a result, the Fixed Doppler Flow Switch plays a crucial role in maintaining efficient industrial processes.

-

HVAC systems require proper monitoring to ensure that they function optimally. To this end, Fixed Doppler Flow Switches offer a reliable solution for monitoring the flow of air or water in such systems. By providing real-time information about the flow rate, these switches help identify any inefficiencies or malfunctions. Moreover, they enable HVAC technicians to adjust and fine-tune the system for better performance. In addition, the use of Fixed Doppler Flow Switches can ultimately improve the efficiency and longevity of HVAC systems, thereby reducing energy costs and enhancing overall functionality.